Pro. Dr. Hassan Khalid Hassan Al-Ogaidi

Citric Acid is an organic acid used widely in our daily life, especially in our food and food industry and medicine. In general Citric Acid is a preservative substance used in adding a tasty magical flavor to food.

The discovery of citric acid has been credited to the 8th century Arabian Alchemist Jabir Ibn Hayyan, from citrus fruits. In the 13th century, the scientist Vincent recorded the first image of the acid, followed by the Swedish chemist Carl who isolated it and crystallized in 1784.

In 1860, Citric acid produced from lemon in Italy. In 1983, the scientist C. Wehmer discovered that Penicilium mold could produce citric acid from sugar. However, microbial production of citric acid remained limited (laboratorial). In 1917, the American food chemist James Currie discovered that Aspergillus niger mold could be efficient citric acid producers, and began industrial-level production using this technique. In 1929, acid was artificially produced using A. niger mold on a different environmental substances like: Sucrose, Glucose, Corn Syrup, Molasses, Solved Starch and finally Dates.

Dates are the most important sources and the cheapest ones in the Arabic Homeland; the global consumption of Dates in 1986 was 350 thousand ton per year. In 2000, there was an increased demand of Dates per year reaches 600 thousand ton. To reach a maximum rate exceeding 6*105 ton per year. 70% of the produced acid used in soft drinks, 18% is in different industries and the remaining 12% for other purposes, all of it is from fermentation sources.

Citric acid produces as follows:

1- From citrus fruits, as in Mexico and South America countries with a percentage of 1% from the world production, where economically producing lemon from citrus fruits.

2- The chemical composing method, which an expensive one.

3- Fermentation methods in three used ways, there is a 4.5*105 ton per year of Citric acid produced by fermentation of A. niger. As in the following:

A) The Japanese method (Koji), used in 1966, where the interaction was not liquid but has an amount of humidity. The materials used in this method were: starch, fibers, Potatoes, Rice grain, and oat.

B) Superficial Method.

C) Obscured Method.

The best one of them is the Obscured Method due to its simplicity and cheapness.

Living producing Citric Acid:

A) Bactria, as:

1- Bacillus Sp.

2- Brevibacterium flavum.

3- Arthobater.

4- Corynebacterium spp.

B) Molds, as:

1- A. niger.

2- A. awamori.

3- A. foetidus.

4- Mucor

C) Yeasts, as:

1- Candida lipolytica.

2- C.citrica

3- S.cervisaie

The best result in producing Citric Acid is by using the mold A. niger.

Dates and Citric Acid production by using A. niger mold

In Iraq and the other Arabic countries, Dates considered being the greatest sours of import, which witnessing a rapid increase due to the increased attention form the government specially in developing palm trees fortune and Dates.

Dates vary in its consumption, whereas there are Dates for direct consumption and there are Dates for industrial purposes.

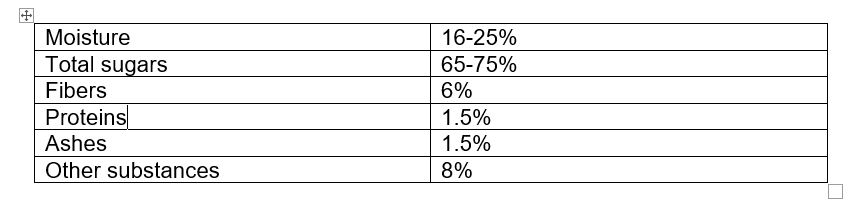

One of the most important kind of Iraqi Dates is Zahdi as well as the third degree Dates. These kinds of Dates enjoyed a high rate of moisture reaches 18-25%, with a sugar content of 65-75 % with fibers and Vitamins and Amino Acids and minerals, the below table shows its percentages:

Dates are a big source of many diversified industries: Pastry, Soft Drinks, Alcohol, Vinegar, Sugary Solutions, Molasses, Ice Cream, Carmel, single Cell Protein, and finally Citric Acid, due to its high concentration of Carbonic source which is Sugars.

Citric acid is one of the organic acids, greatly needed in the global market as we mentioned earlier, because it is used in many food and chemical industries.

Acid Producing Process (Citric Acid from Dates)

For starting producing Citric Acid from Dates, we need the following:

1- Plenty of cheap Dates, with a production unit for making the pure Dates juice from minerals.

2- Plenty of productive breed of Aspergillus niger mold.

3- Microbiological experience (Microbiology) and new lab.

4- Preparing the nutritional environment necessary for the mold.

5- Distribution of food environment.

6- Process of fixing the necessary conditions of production.

7- Acid extraction process from the nutritional environment medium.

At the beginning, high efficient mold producing citric, that needs to survey and selective all verities of wild mold available in the region and determine the best of them, that happens by transforming the sugar to an acid or by buying the mutant from the banks spread and available in the world, after fixing the required characteristics, then desired mutant is the one who make a genetic leap.

Aspergillus is an aero mold generally grows on the environmental surfaces and it is a common polluter for the starch food and carbohydrates.

Preparation of the Laboratorial Nutritional Environment to Mold Grow

1- Culturing the selective mold on a Potato Dextrose Ager medium, on a temperature of 4oc.

2- Make permanent incubating for 15-30 days on a temperature of 30 o c, till the size of mycelium reach 4 mm, then sterilizing transfer it to a beaker of treated and sterilized Dates juice for 5 days.

3- Prepare the juice (Dates Juice) by using 1 kg of Dates for 3 litters of Water, extraction process will finished on the temperature of 60-70 o c, in a blender for half an hour to 45 minute. Then sit the juice and start the filtration process through filters, then the alleviation process started to the concentration of 25%, after sterilizing, filtering and treatment of removing heavy metals in the 250 litter beaker, distribute it. Each beaker should contain 50 ml of the juice after modifying PH; sterilize it less than 121 o c for 5 minutes. Afterward start fertilize the beaker with Slant breed and raise it in the temperature of 30 o c.

How to Extract heavy Metals in Dates Juice

First:

1- Alleviate the Juice (Date Juice).

2- PH modification till 7, using IN NaOH.

3- Adding 1-2% weight per size from Tri Calcium Phosphate.

4- Heat the mixture till 100 o c for five minutes.

5- Cool the mixture.

6- Centrifuging expel at 4000 rpm per minute for 20 minute.

7- PH modification till 6.5, using IN HCl.

Secondly:

Treating the Dates juice by reducing the PH till 6.5, then adding 25-50 microgram per one ml of Potassium Ferosinide for metals settling.

Thirdly:

It is possible for the Dates juice to be treated by some concentrations of Methanol, if needed, where the addition will happen in the third day of fermentation process.

Sugar concentration for mother culture preparing process

Occurs by using different concentrations of Sugars, between 9-25%.

Produce the Mold artificially using Dates Juice

1- Prepare the mother culture

2- Using Pellets between 120*103 to 280*103 inside the (flask), which used as ferments mother culture in the levels of 2%. The radius of the perfect pellet is between 1.2-2.5 mm after 5 days. Science refer to Pellet farm is must to have the minimum viscosity depending on blending degree and ventilation of minimum amount of O2, whereas Morphology mold pellets during the acid production with include the circulate pellet to free long parts, basing on the environmental medium as well as the genotype of the breed, and all the growths have specific characteristics depending on growth energy and nutrition’s consumption.

Typical Growth of the A. niger Mold for producing Citric Acid

1- Fast growth phase: the mold fast growth is followed by slow growth, this change in growth average dedicate the physiological state of mycelium than the normal growth, which result acid. Thus it goes through the following phases:

1) Hyphe growth.

2) Pellet growth.

3) Fixed and Strong growth.

4) Transmitting between idio phase and tropho phase.

5) Idio phase growth.

6) Citric acid forming.

Why the Obscured Agriculture?

1- Provide the highest level of production.

2- Less size.

3- Much cheaper.

Biochemical Process of Citric Acid production

The biochemical process to produce Citric Acid using A. niger mold is as in the following. It depends basically on Tricarboxilic (TCA) cycle which works as:

1- Hexsugar breaking to birovat and estel COA.

2- Forming Estets Ogsalic.

3- Condensing Asytel COA and oxaloacetate to citric acid

Pyruvate+CO2+H2O+ATP= Oxatoacetate+ ADP+ pi

Carboxy phosphosr- Enoil pirovat (PEP) solved by PEP carboxy ether

PEP ADP O2 oxaloactate ADp

Factors Influence the Fermentation Process

1- Environmental contents: metals splits feedings have an essential part in producing 1 gm of citric acid per 1 gm of sugar.

a) Zinc (Zn) must be in the critical quantity, because it is an important factor in organizing and growing and accumulating of strains, the maximum limit should be 0.2 mm.

b) Manganese (Mn) which played an essential role in organizing the growth and accumulating of strains by using A. niger, where its ultimate concentration is 0.2mm. Any change in metal’s amount will effect the productivity of the acid and reduce it or short it in about 10-25%, as it effect the fat level in mycelium.

c) Cupper (Cu) also has a big role in shortening the acid; its concentrations should be 40 parts per one million.

d) Iron plays an important role in fermentation process and acid productivity.

e) Primary Sugar: the Sugary Carbonic Sours must be 15-18% weight per volume in nutritional environment. Higher consternation of sugars will lead to big sugary residue after fermentation process, which is not economic.

f) ferrocynid Ions: adding potassium ferocynid does not affect the carbon, Nitrogen, Phosphoric content in the nutritional environment, but it does shortening the gray content though the ferrocynid does not add through the growth phase.

g) Fermentation timing: the best nurture of an ideal timing to reach higher productivity depends on: mold efficiency, fermentation circumstances of the obscured agriculture then the perfect timing will be 4-5 days, where the minimum amount of Citric acid show that could reach 8-9 days.

h) Ventilation and movement in the obscured farms does not necessarily lead us to growth but also give us bigger amounts of Citric acid. The Oxygen source should be pure and sterilized, any stop in the movement process or ventilation will give an opposite effect for acid productivity. The degree of ventilation must be 0.6 wm, and the speed of agitation process is between 400-700rpm per minute, because any extra speeding will lead to produce pallets and reduce the acid productivity. Thus, O2 amount affect Manganese Ion on growing A. niger and the types of pellets.

i) Temperature degree of Fermentation process: the heating degree is an essential part in mycelium evolution as well as Citric acid productivity. The ideal temperature is 25-30o c, higher temperature than this will work to citric acid productivity and will lead of producing Oxalic acid.

j) PH level: PH is very important in the beginning of fermentation process, best result for producing Citric acid is by (5.4- 6) PH in environmental medium (Dates Juice). However, the ideal PH is determined by the mold status. High PH level will lead to accumulation of Oxalic acid instead of Citric acid. Lower PH level will lead aborting of the A. niger mold growth. Thus, preserving the suitable PH level for the mold breed is greatly important.

k) Auxiliary materials in the productive process activity:

There are a lot of helping factors and energetic for the fermentation process, as in the following:

1. Methanol.

2. Biotanol- which has a reversing effect for acid productivity.

3. Anti-foam: which increase the transmitting level of O2 in movement, as:

A. Soy beans.

B. Silicon.

C. Polypropylene glycol.

These substances increase acid productivity (Citric Acid). The ideal concentration of Alcohols is 1-4% of size, which gives high purity and high productivity.

Fats: have an important role by increasing productivity of 20%, and addition Oleic acid (v/v).

Vitamins: added to increase the productivity of Ascorbic and Benzoic and riboflavin, Thymine in concentrations of 1*105 – 5*105.

l) Titration Source: another important part in the growth and development process of the mold thus in acid productivity. Its concentration is 0.5%. most important compounds are: ammonium Sulphate and Aluminum nitrate potassium nitrate.

m) Phosphate (P): it has an important role in the growth and development process of the A. Niger mold, with a ratio of 0.05% in the nutritional environment.

n) Amino acids: amino acids have an essential role in the production process, specially the :lectern, Lysine, Aspartic, glotamic.

Toxics Materials of Production

1- phenolat

2- Resorcinol.

3- Cresol.

4- Naphtha.

5- Hydroquinone.

Mutations

Chemical and Physical factors affect the citric mutation of A. Niger, in certain concentrations and doses, some of those factors are:

UV rays

X rays

Gamma rays

Chemical Materials

1- Ethel Methane Sulphate (EMS).

2- Di Ethyl Sulphonate (DES).

3- N-Methyl.

4- N-Nitro.

5- Antibiotics.

How to Calculate Productivity?

Citric acid productivity operation calculated as in the following equation:

Amount of Citric Acid * 100% Amount of Sugar

The highest productivity of citric acid resulted from Dates juice was about 75-89% in Iraq and 114% in the world

References:

• Hasan Al-Ogaidi , 2000 , Biotechnology and industrial microbiology

• دار زهران للنشر والطباعة – عمان

• Mr. Alsayyed Alsayyed Wajeeh, 2003 , Biotechnology and agricultural applications

• دار الوفاء للنشر – الاسكندرية

• Abdel Wahhab Abdel Hafez , 2001 , Fundamentals of industrial microbiology

• Beshkov, M., 1974 , Industrial Microbiology-Cresto danal-Bulgariaplovdiv

• LELAND A. UNDERKOFLER, Richard J. 1954, Industrial Fermentations Vol.1

• Chemical Pu;ishing Co. INC. New York NY.

• The Citric Acid Fermentation M. J. Johnson 1954

• Anon. Chem. Inds. 68.19 (1951)

• Reed , G(1982) Industrial Microbiology Avi Publishing Company INC Westport Connecticut

• Briton M. Miller, Warren Lusky 1976, McGraw-Hill, Inc.

• العكيدي حسن خالد، التقنية الحيوية والتمور، FAO 1987

• المراغي سعد شحاته محمد، 1994، مقدمة في علم الفطريات

• العكيدي حسم خالد 1983، تكنولوجيا انتاج حامض الليمون عن طريق الاحياء المجهرية، دراسات وتقارير الامانة العامة للاتحاد العربي للصناعات الغذائية، بغداد – العراق.

بيئة أبوظبي وسيلة إعلامية غير ربحية مسؤولية مجتمعية تملكها مجموعة نايا للتميز

بيئة أبوظبي وسيلة إعلامية غير ربحية مسؤولية مجتمعية تملكها مجموعة نايا للتميز